Introduction

Skincare products use either liquid-based or dry masks to deliver the active ingredients. Liquid-based delivery is limited since the active ingredients do not adhere well to the skin, preventing adequate absorption. Dry masks usually include chemical preservatives to maintain the shelf-life of active ingredients.1 A promising alternative is to use electrospun nanofiber-based masks. Electrospun nanofibers can be fabricated with the active agents integrated into the fibers, thereby eliminating the necessity of using chemical preservatives.2 The high surface area of nanofibers allows for larger skin contact and enables rapid absorption of active ingredients.

Skincare

The skin is a complex tissue that consists of many natural ingredients that maintain elasticity, smoothness, and youthfulness. Collagen, the most abundant protein within the skin, provides the elasticity necessary to produce smooth and youthful skin.3 Hyaluronic acid plays an important role in skin healing, and hydration, and stimulates collagen production.4 Other active agents that help maintain skin health include fibronectin, laminin, and elastin.3 Incorporating these active agents within cosmetic facemasks is critical for promoting healing and anti-aging properties.

Cosmetic masks are generally manufactured as dry sheets and soaked in active ingredients1. Artificial preservatives are commonly used to sustain the shelf-life of the cosmetic mask. Common preservatives include alcohols, isothiazolones, and phenol derivatives. While many of these preservatives have antimicrobial benefits, they pose some level of toxicity or irritation to the skin. Cosmetic masks also have poor adhesion to the skin. Therefore, the active ingredients must be released very quickly which causes inadequate absorption into the skin.

Nanofiber Cosmetic Masks:

Nanofiber masks are composed of fibers that are 1000 nanometers or less in diameter.5 These small fibers have a large surface-to-volume ratio that results in a high loading rate and promotes great contact and adhesion to the surface of the skin.6

Electrospinning is a common technique used to fabricate nanofiber materials. During the electrospinning process, a polymer solution is extruded into a highly charged electric field and is propelled toward a grounded or negatively charged collector. During the time of flight, the solvents evaporate, and the polymer is collected in the form of a nanofiber sheet that can range from 100 nanometers to a few microns in diameter. The polymer solution can be tuned to incorporate active ingredients such as hyaluronic acid and collagen that promote skin healing and antiaging characteristics.7 Due to these skin-active ingredients being blended within the fiber structure, there is no necessity to use any chemical preservatives.

Electrospinning Hyaluronic-based Nanofiber Cosmetic Masks

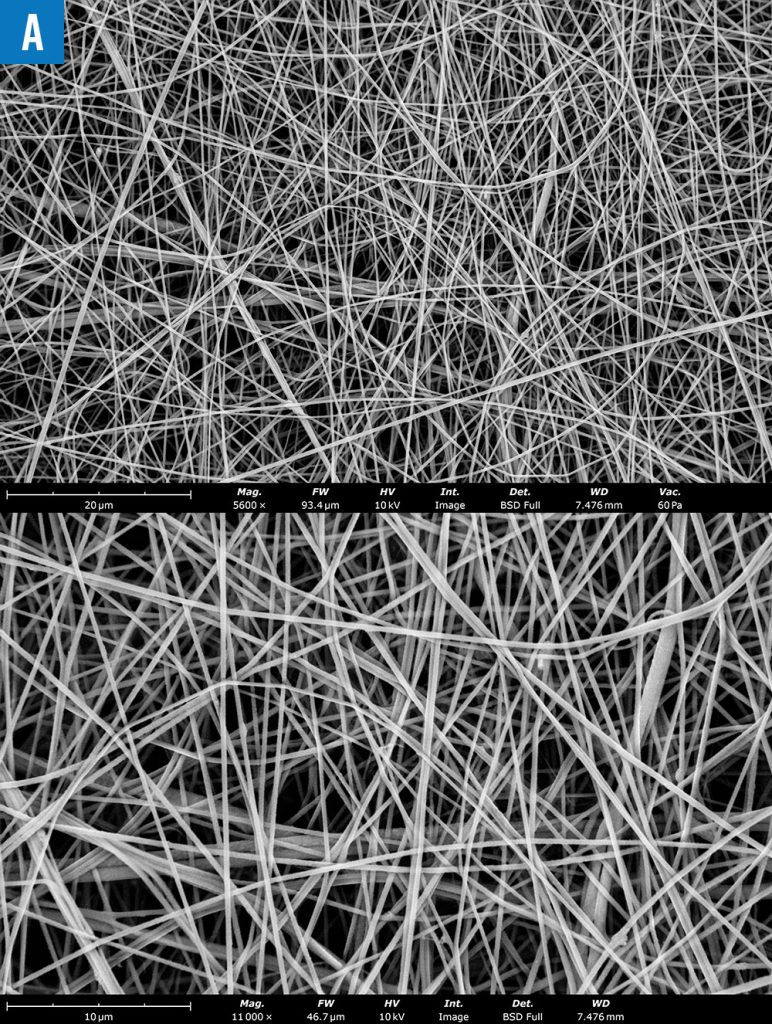

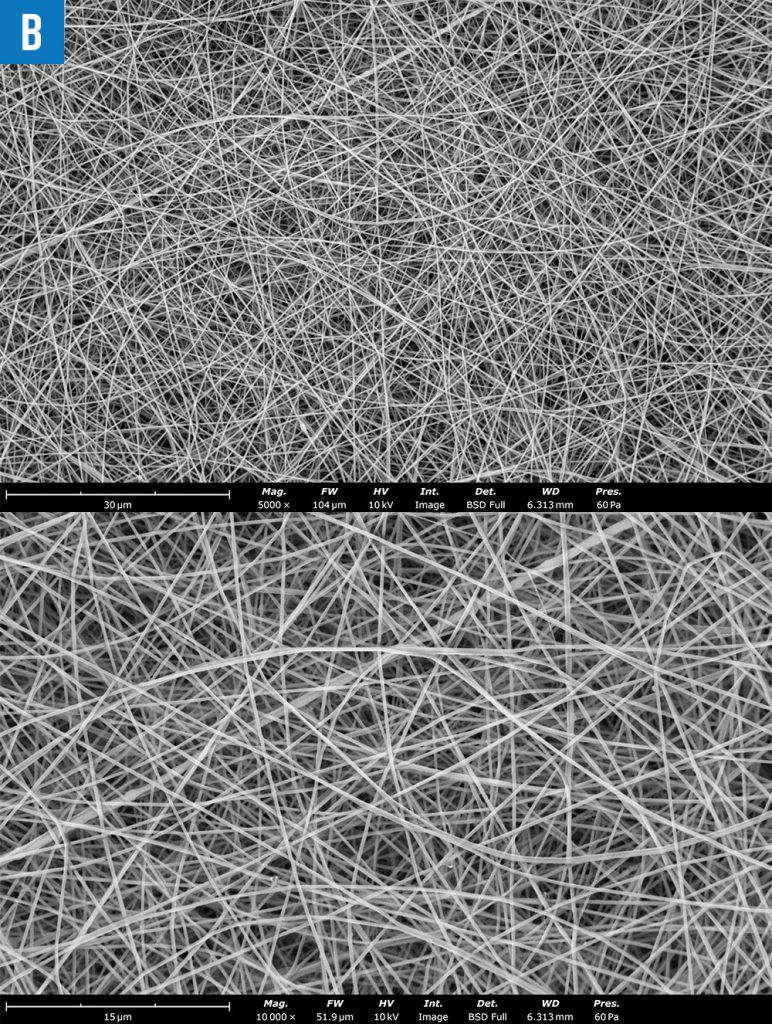

Polyethylene oxide (PEO) is a common material used in the cosmetic industry and can also be easily electrospun to generate nanofibers. Sheets of electrospun nanofibers can be fabricated as shown in Figure 1. To demonstrate the use of electrospun sheets for cosmetic applications, a blended solution of PEO and hyaluronic acid was dissolved in a phosphate-buffered saline solution and was electrospun to develop PEO/Hyaluronic acid nanofiber sheets. Scanning electron microscopy imaging revealed the presence of smooth hyaluronic acid nanofibers that are suitable for cosmetic beauty masks (Figure 2A). The resulting mat was a dry nanofiber sheet without any presence of artificial preservatives.

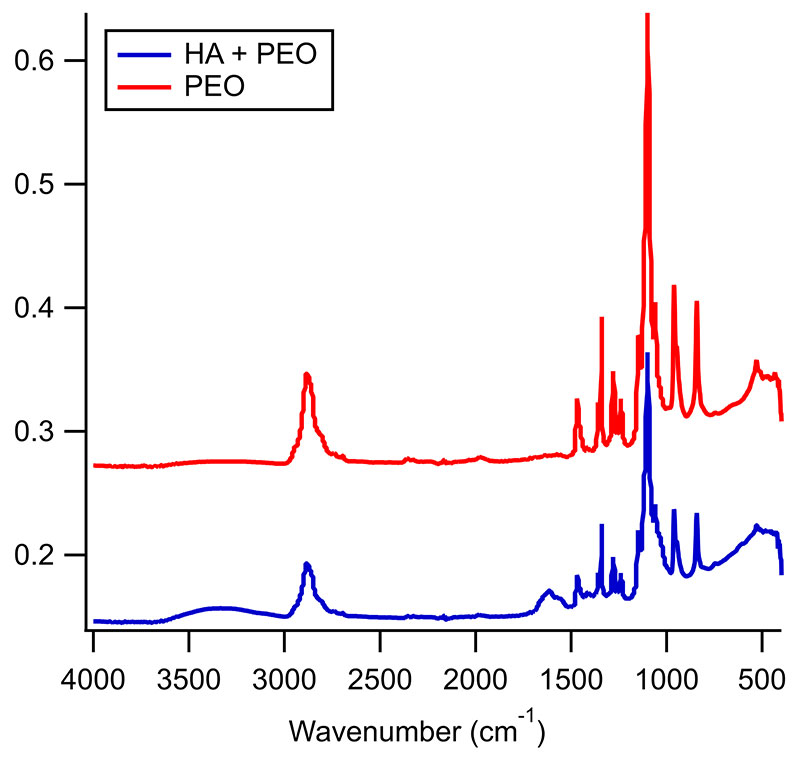

After forming the nanofiber PEO/hyaluronic acid sheets, the cosmetic product underwent Fourier Transform Infrared Spectroscopy (FTIR) analysis to confirm the presence of active agent hyaluronic acid within the fibers. Compared to the control PEO mat, the PEO/hyaluronic acid fiber mat had specific FTIR peaks at 3500 cm-1 (corresponding to hydrogen bonding within hyaluronic acid), and 1650 cm-1 (corresponding to C = O group present within hyaluronic acid) (Figure 3).8 Successfully incorporating hyaluronic acid within the nanofiber sheets display the simplicity and ease of making nanofiber cosmetic masks with antiaging and skin healing ingredients.

Conclusion

Current cosmetic face masks have poor skin contact, use chemical preservatives, and have difficulty delivering anti-aging ingredients into the skin. Utilizing electrospinning is a simple technique to develop nanofiber cosmetic masks. The nanofiber structure has a high surface area that allows for excellent skin contact. These nanofiber materials can be incorporated with antiaging ingredients as a dry sheet and do not require any chemical preservatives. Confirming the presence of hyaluronic acid within the nanofibers shows promise that electrospinning is a great technology that can be utilized for developing cosmetic masks.

References

- Xu, H., Wu, Z., Zhao, D., Liang, H., Yuan, H., & Wang, C. (2022). Preparation and characterization of electrospun nanofibers-based facial mask containing hyaluronic acid as a moisturizing component and huangshui polysaccharide as an antioxidant component. International Journal of Biological Macromolecules, 214, 212-219. ↩︎

- Manatunga, D. C., Godakanda, V. U., Herath, H. M. L. P. B., de Silva, R. M., Yeh, C. Y., Chen, J. Y., … & Nalin de Silva, K. M. (2020). Nanofibrous cosmetic face mask for transdermal delivery of nano gold: synthesis, characterization, release and zebra fish employed toxicity studies. Royal Society open science, 7(9), 201266. ↩︎

- Potekaev, N. N., Borzykh, O. B., Medvedev, G. V., Pushkin, D. V., Petrova, M. M., Petrov, A. V., … & Shnayder, N. A. (2021). The role of extracellular matrix in skin wound healing. Journal of Clinical Medicine, 10(24), 5947. ↩︎

- Yang, H., Song, L., Zou, Y., Sun, D., Wang, L., Yu, Z., & Guo, J. (2020). Role of hyaluronic acids and potential as regenerative biomaterials in wound healing. ACS Applied Bio Materials, 4(1), 311-324. ↩︎

- Ashok Chand, N., Duarah, S., Ah Yuk-Winters, B., & Fomra, D. (2024). Clinical Investigation of Collagen-Based Electrospun Nanofibers for Enhanced Delivery of Skincare Ingredients. Cosmetics, 11(1), 18. ↩︎

- Teno, J., Pardo-Figuerez, M., Hummel, N., Bonin, V., Fusco, A., Ricci, C., … & Lagaron, J. M. (2020). Preliminary studies on an innovative bioactive skin soluble beauty mask made by combining electrospinning and dry powder impregnation. Cosmetics, 7(4), 96. ↩︎

- Kong, B., & Mi, S. (2016). Electrospun scaffolds for corneal tissue engineering: A review. Materials, 9(8), 614. ↩︎

- Chen, H., Chen, X., Chen, H., Liu, X., Li, J., Luo, J., & Xu, S. (2020). Molecular interaction, chain conformation, and rheological modification during electrospinning of hyaluronic acid aqueous solution. Membranes, 10(9), 217. ↩︎