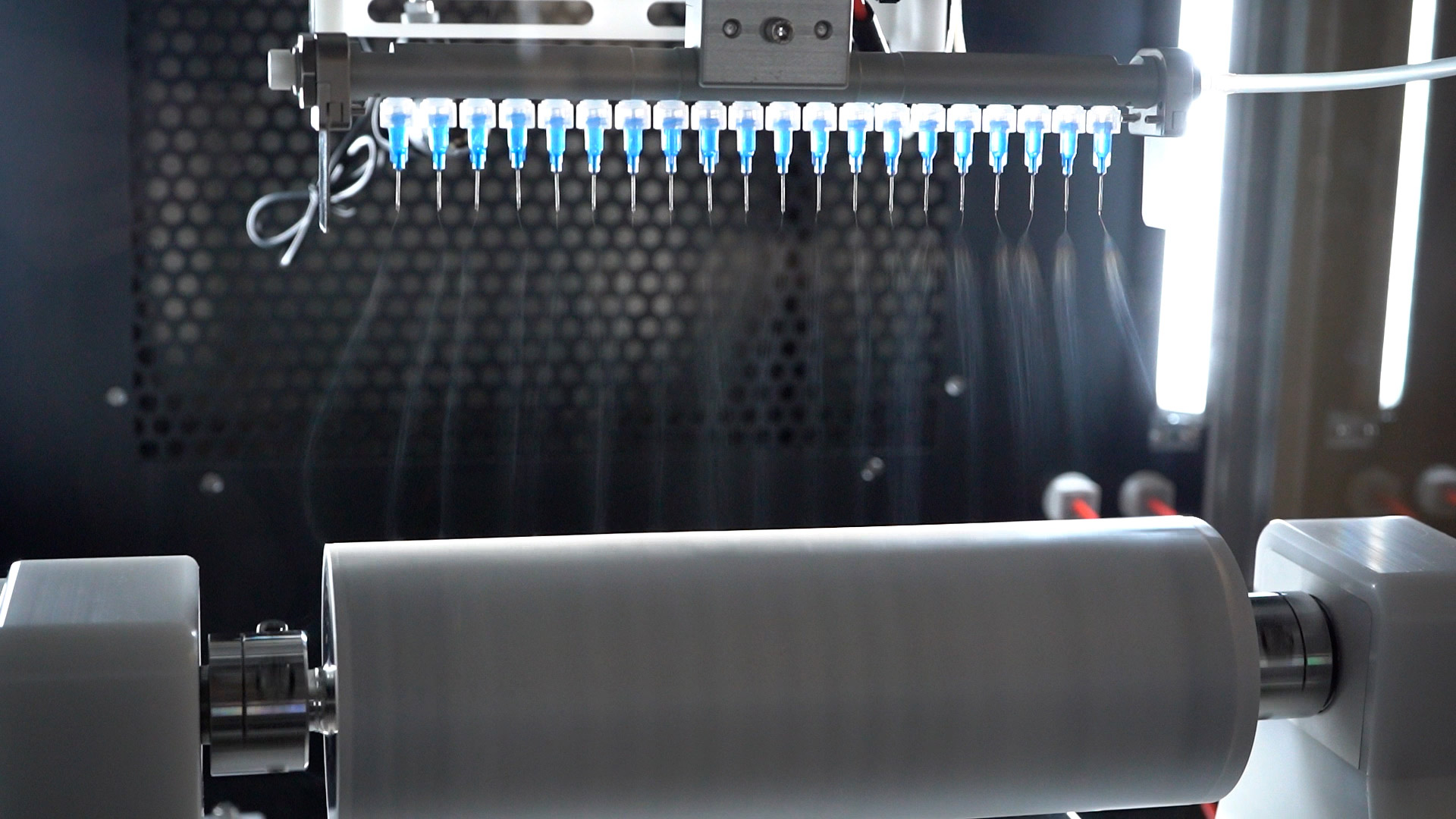

Electrospinning & Electrospraying capabilities

Electrospinning Services at Nanoscience Analytical

Nanoscience Analytical offers a comprehensive suite of electrospinning services designed to support innovation across a range of industries, including biomedical, pharmaceuticals, filtration, and advanced materials.

Our services include Proof of Concept (PoC) development, where we help clients explore the potential of electrospinning for their specific applications by creating customized nanofiber prototypes.

We also offer Process Optimization, refining electrospinning parameters to ensure high-quality, consistent nanofiber production tailored to precise needs such as fiber diameter, porosity, and strength.

For clients looking to scale production, our Scale-Up services assist in transitioning from lab-scale electrospinning to pilot-scale commercial manufacturing, ensuring efficiency, consistency, and regulatory compliance.

Through these offerings, Nanoscience Analytical provides expert guidance and cutting-edge technology to enable the successful development and commercialization of electrospun nanofiber products.

We Offer:

- Nanofiber and Nanoparticle Fabrication: Fabricate high-quality nanofibers via electrospinning and nanoparticles through electrospraying for diverse applications.

- Tailored Electrospinning Solutions: Leverage our expertise in processing a wide polymer library to develop customized electrospinning solutions for specific needs.

- 3D Structure Fabrication: Produce complex 3D structures like sheets, tubes, and cylinders using nanoscale electrospun fibers for enhanced functionality and performance.

- Uniform Coating for Medical Devices: Achieve precise, uniform coatings on intricate architectures such as stents, catheters, and other implantable medical devices, enhancing their biocompatibility and effectiveness.

Capabilities:

Our state-of-the-art laboratory is equipped with benchtop systems and roll-to-roll fabrication capabilities, enabling the coating of complex 3D devices. Paired with our expert team, which has years of experience in process and product development, we offer an iterative optimization process to ensure top-quality results. This process is supported by a variety of advanced analytical techniques, including:

- Scanning Electron Microscopy (SEM): For detailed morphological analysis of fibers and particles.

- Solution Characterization: Assessing key properties like viscosity, conductivity, and surface tension.

- Optical Tensiometry: To evaluate wettability and surface interactions.

- Pore, Particle, and Fiber Size Analysis: Utilizing statistical methods for precise measurement and control of pore size, particle size, and fiber diameters.

This comprehensive approach ensures precision, quality, and consistency in all aspects of nanofiber and device fabrication.

- Apply electrospinning expertise to offer innovative solutions to your product development.

- Evaluate emerging ideas and concepts for feasibility in fabricating electrospun materials.

- Electrospinning expertise and best in class equipment combine to achieve unique formulations of polymers in combination with devices.

- A robust design of experiment plan is applied to each project to achieve design specifications.

- Method development for the delivery of consistent and reproducible processes in sample formulation.

- Suite of characterization techniques to optimize solutions to finished products.

- Pilot scale formulation development processes.

- Production capabilities for fabrication of rolls of electrospun sheets of several meters.

- Transfer of technology for continued development in your facility.

Contact Us

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.