SEM & Elemental Analysis

Why Choose Nanoscience Analytical?

Nanoscience Analytical provides SEM and EDS analytical services by leveraging advanced instrumentation and highly skilled scientists. Our laboratory is equipped with several SEMs with multiple detectors, electron source types, and software packages for automated analysis to provide you with fast and accurate results.

Capabilities

Sample size: up to 100 x 100 x 40 mm.

Resolution: up to 2 nm

Detectors:

BSD – Elemental contrast

SED – Surface morphology

EDS – Elemental composition

STEM – Transmitted images

Automated data collection and analysis

Common Samples: Wafers, Cross sectioned layers, Powders, Thin sections, Coatings, Nanoparticles, Fibers, Metallurgical samples.

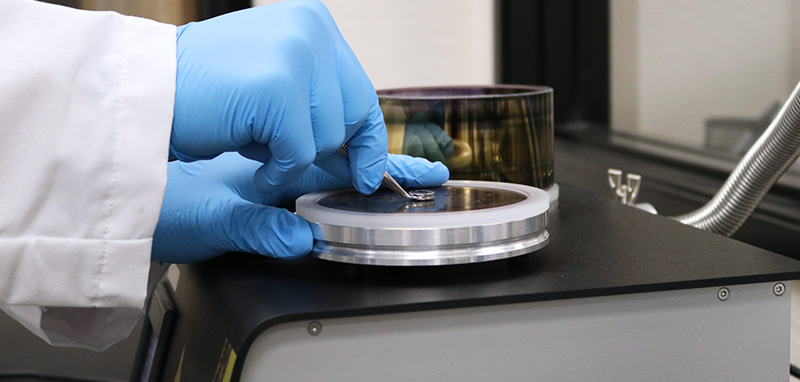

Sample Prep

SEM sample preparation is critical for achieving high quality SEM images, some methods include:

Mechanical cutting/polishing

Cross sectional polishing / ion milling

Coating non-conductive samples

Non destructive sample mounting

Powder dispersion

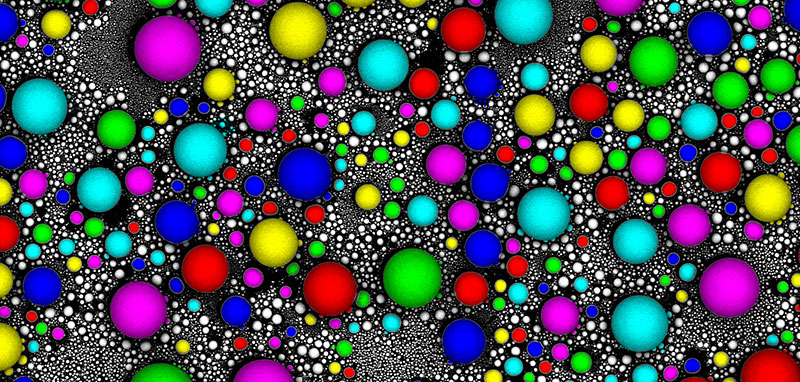

Statistically Relevant Results

Large datasets collected and analyzed through automated routines, eliminating user biases.

Particle analysis – detect impurities, foreign particles, or contaminants in your process.

Fiber analysis – Diameter, orientation, and morphology.

Inclusion analysis – compliant with ASTM E2283 standards.

Technical cleanliness – compliant with ASTM 16232 and VDA 16 standards.

Custom reporting to meet specific standards.

Talk to a scientist today!

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.

SEM Capabilities:

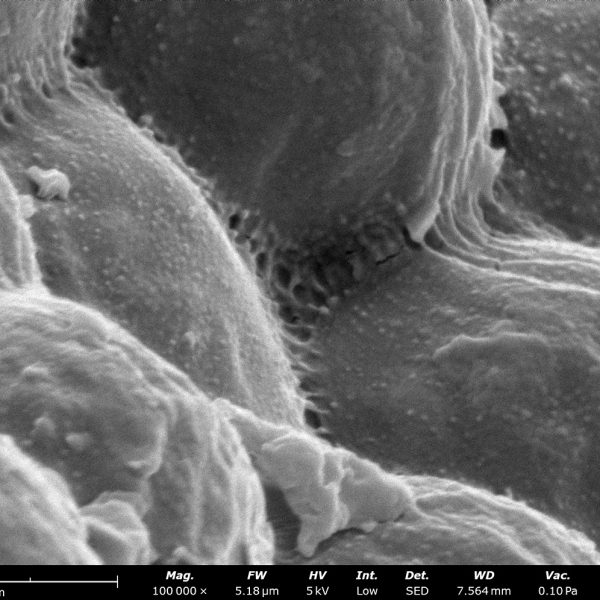

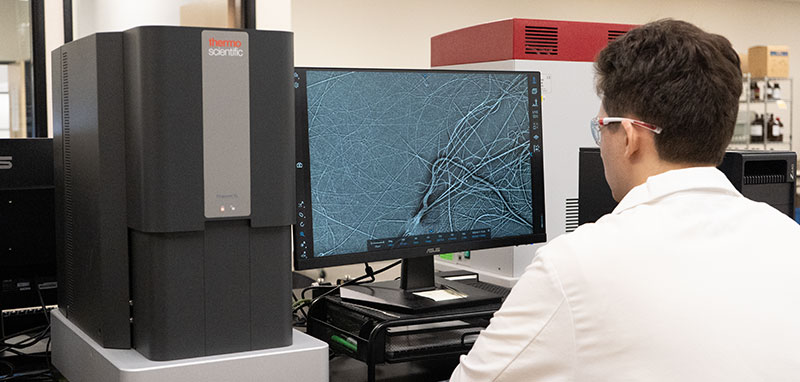

High Resolution Imaging

Visualize your materials' surface morphology and topography at the nanoscale with exceptional clarity and precision and identify critical defects, interfaces, or features of interest.

Elemental Analysis (EDS)

Point, line scan and area mapping are available. EDS maps can be acquired up to 960×960 pixels and line scans of 512 pixels. The elemental detection capability is from Boron to Americium.

Sample Prep

Methods include: non-destructive sample mounting, non-conductive sample coatings, mechanical cutting/polishing, cross sectional polishing, and powder deposition.

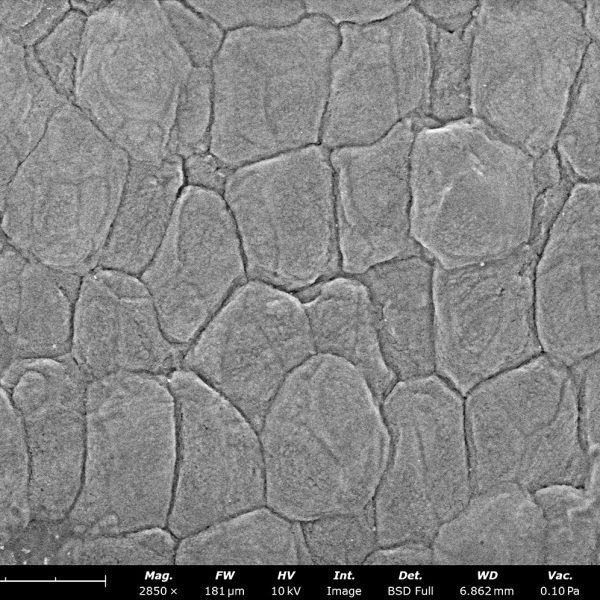

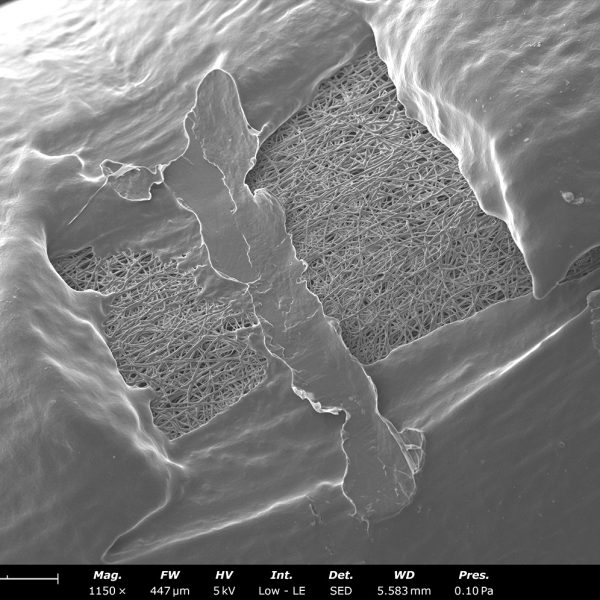

Fiber Analysis

Automated fiber analysis via SEM imaging produces accurate size and orientation information of micro and nanofibers, including complex fiber networks.

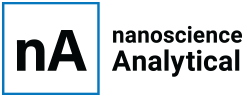

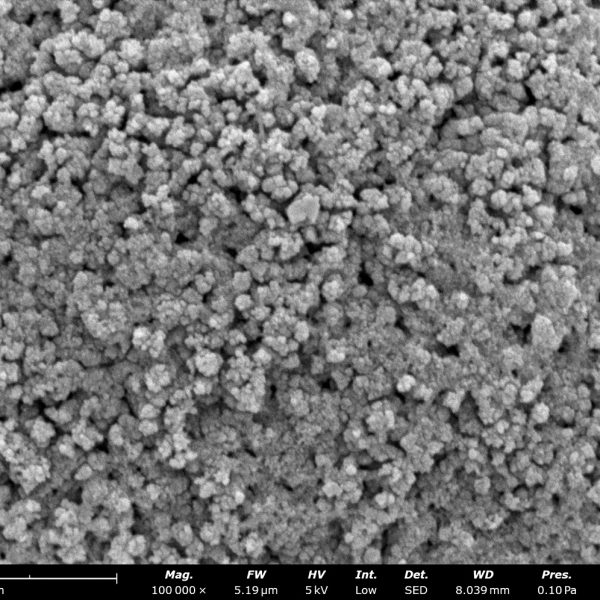

Particle Analysis

Automated, high-speed analysis to gather statistically relevant and accurate data on particle size and morphology of submicron particles. Pair with EDS for particle-by-particle compositional analysis.

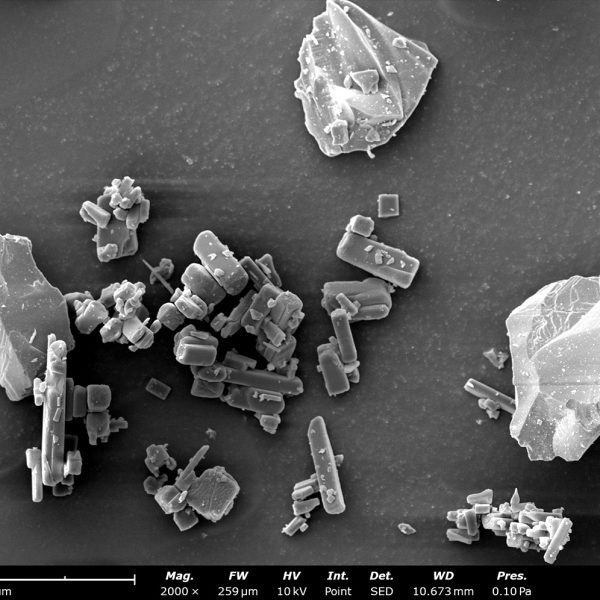

Pore Analysis

Automated pore analysis measurements provide a better understanding of the characteristics of porous materials by providing pore sizes, aspect ratios, and distribution of pores.

Contact Us

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.