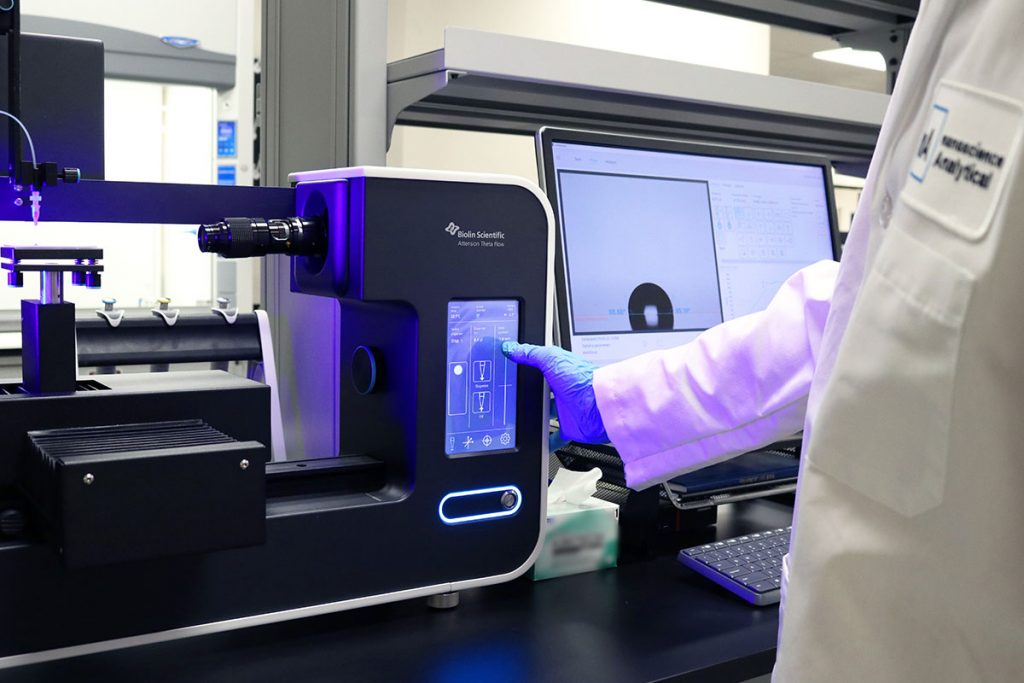

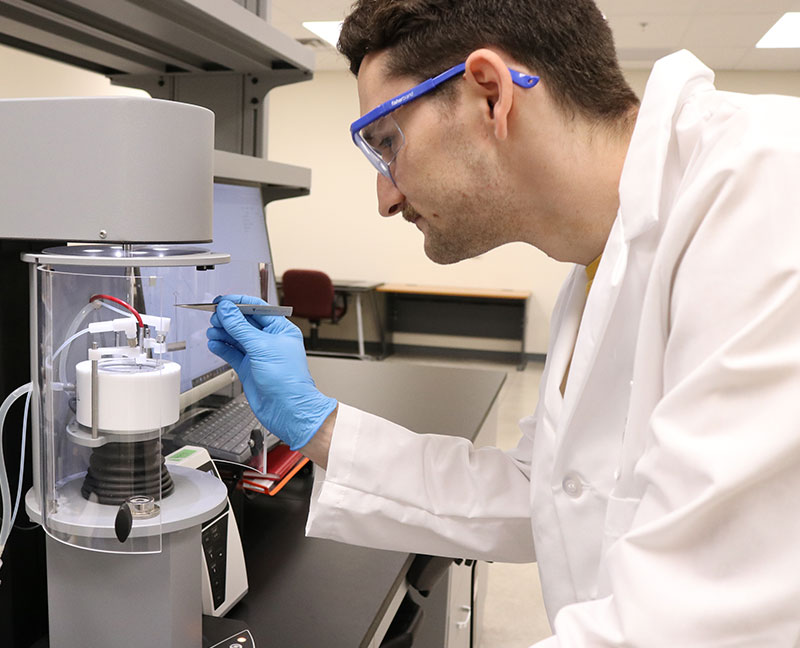

Contact Angle Goniometry & Surface Tension Measurements

Optical & Force Tensiometry

We offer static and dynamic optical and force tensiometry for surface tension measurements, contact angle measurements, and surface free energy measurements with high precision.

These techniques are used to characterize material surface properties and interfacial interactions between gas, liquid, and solid phases. Also known as contact angle goniometers or contact angle meters, they are instruments of choice to characterize surfaces. Our heavily accessorized instruments can accommodate many different materials for a wide variety of applications.

Standard Capabilities:

Static Contact Angle

Sessile drop or meniscus methods

Contact angle measurements reveal hydrophobicity/hydrophilicity, the efficacy of surface treatments, and the wettability of your substrate’s surface.

Dynamic Contact Angle

Tilting drop, Wilhelmy plate/fiber, or

Automated needle-in drop volume methods

Advancing and receding contact angles along with the contact angle hysteresis indicate surface chemical or topographical heterogeneity, provide the most reproducible measurement of surface wettability, predict adhesive behavior of coatings, and many other application areas.

Surface Tension

Pendant drop/bubble, du nouy ring, or wilhelmy plate methods

Drop shape analysis and force tensiometer probe measurements to determine the surface tension of liquids at low volumes and under dynamic or equilibrium conditions.

Additional measurements

Surface Free Energy Measurement

Sessile drop, wilhelmy plate, meniscus, or washburn methods

Surface free energy (units of mN/m or dynes/cm) uses contact angle measurements from several probe liquids to deliver a comprehensive assessment of your surface’s wetting properties, including contributions from polar, dispersive, and acid/base molecular interactions.

Powder Wettability Measurement

Washburn or sessile drop methods

This technique can determine the contact angle between a solvent and powder, particles or bundle of fibers, such as samples relevant to pharmaceuticals, cosmetics, clothing, and more.

Roughness-corrected Static Contact Angle

Sessile drop method with topography measurement

This technique involves a precise roughness measurement followed by a contact angle measurement at the same location to provide a more complete picture of wettability. The roughness correction allows for the decoupling of a substrate’s surface chemistry from its 3-D topography which contributes to the overall wettability as measured via contact angle.

Interfacial Tension

Pendant drop and du nouy ring methods

Drop shape analysis and force tensiometer measurements can measure the interfacial tension measurements between two immiscible liquids, such as oil-water systems.

Critical Micelle Concentration (CMC)

Pendant drop/bubble method, du nouy ring method, or wilhelmy plate method

Surface or interfacial tension measurements over a wide range of surfactant concentrations are used to establish the surface tension as a function of surfactant concentration and determine the point of CMC.

Dilatational Interfacial Rheology

Pulsating drop/bubble method

This technique provides the complex dilational modulus for a droplet/air or droplet/immiscible liquid interface, including the viscous and elastic components, indicating the stability of foams, emulsions, or other viscoelastic films.

Liquid Density

Buoyancy force measurement

The density of a liquid is measured with high precision by measuring the buoyancy of a solid with well-defined geometry when immersed in the sample liquid.

Contact Us

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.