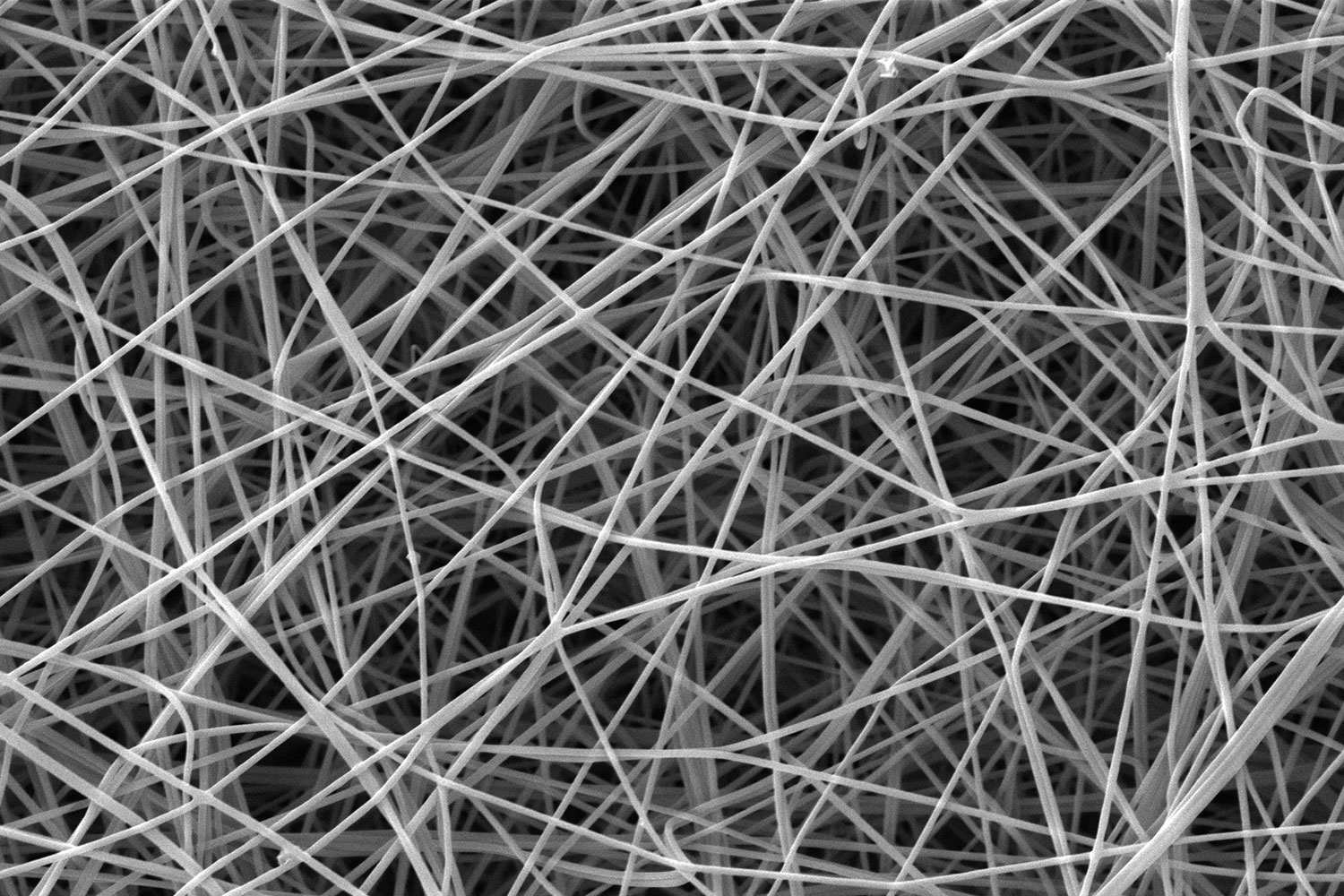

Electrospinning is a powerful technique for creating nanofibers with applications across biomedical, filtration, energy, and advanced materials. When it comes to developing new electrospun materials or scaling up production, many R&D teams face a critical decision: should you outsource development to a contract research organization (CRO), or bring the equipment and expertise in-house?

When Does In-House Development Make Sense?

Bringing electrospinning equipment in-house can offer significant advantages in terms of control, flexibility, and long-term innovation. For organizations with sustained R&D programs or plans to scale production, internal ownership of the process may be strategically beneficial. However, this path comes with important considerations that must be weighed carefully.

First, the financial investment is substantial. Acquiring electrospinning equipment, outfitting appropriate lab space, and hiring or training personnel all require capital and operational resources. These costs must be justified by long-term research goals or commercial objectives. If the need is short term or exploratory, outsourcing may be more cost effective.

Second, the stage of development matters. Teams still working through proof-of-concept may benefit more from the agility and expertise of a CRO. In contrast, if the process has already been validated and the goal is to scale or customize internally, bringing the technology in-house can offer greater control over timelines, IP, and integration with existing workflows.

Operator expertise is another critical factor. Electrospinning is a highly sensitive process, requiring precise control over variables such as voltage, flow rate, humidity, and solution properties. Without trained staff, achieving reproducible and high-quality results can be challenging. Investing in internal capabilities means not only acquiring equipment but also building technical knowledge to operate and optimize it effectively.

Ultimately, a thorough risk assessment considering technical feasibility, staffing, budget, and strategic goals can help determine whether internal development is the right path. For many teams, a hybrid approach may be ideal: starting with a CRO to validate feasibility and then transitioning to in-house development once the process is proven.

Partnering with a CRO for Electrospinning: Accelerating Innovation with Expert Support

Collaborating with a CRO can be a strategic move for R&D teams exploring electrospinning applications. CROs offer specialized expertise, infrastructure, and flexibility that can significantly streamline development.

One of the most valuable advantages of working with a CRO in electrospinning is the ability to validate feasibility before committing significant internal resources. Electrospinning is a complex process, and not every material or application is suited to it. By outsourcing early-stage development, teams can assess whether their concept is technically viable without investing in equipment, training, or infrastructure prematurely.

CROs bring depth of expertise into electrospinning, allowing them to tailor process parameters such as voltage, flow rate, and collector design to meet the unique performance requirements of your material or device. This targeted approach minimizes trial and error, accelerates optimization, and helps teams reach proof of concept or production readiness faster.

CROs offer a controlled environment to test formulations, optimize parameters, and evaluate reproducibility. This helps identify potential bottlenecks or limitations early on—whether related to material behavior, scalability, or regulatory constraints. It also allows R&D leaders to make informed decisions about whether to proceed with in-house development, scale up, or pivot to alternative approaches.

In short, CROs serve as a strategic checkpoint. They reduce the risk of misaligned investments and provide clarity on whether electrospinning is the right path for your specific application.

Intellectual Property

Intellectual property arrangements with CROs can vary widely, and assuming full ownership of developed materials or processes is not always guaranteed. While some CROs offer models that allow clients to retain IP rights, others may structure agreements around licensing, where the client is granted usage rights under specific conditions. In certain cases, the CRO may retain partial ownership of the technology or require continued collaboration for manufacturing, which can create long-term dependencies.

These nuances have significant implications for commercialization and tech transfer. For example, if a CRO retains control over key process parameters or proprietary formulations, your team may be limited in how the technology can be adapted or scaled internally. Licensing models may also restrict the freedom to modify or repurpose the technology for future applications.

Nanoscience: A CRO Model Built for Flexibility

Nanoscience offers a hybrid model that seamlessly blends contract research services with instrument sales, making it an ideal partner for organizations navigating the transition from outsourced electrospinning development to in house capabilities. This dual approach allows R&D teams to validate concepts, optimize processes, and scale production, while maintaining strategic flexibility.

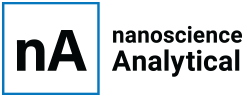

At the heart of Nanoscience’s CRO offering is a dedicated team of scientists and engineers with deep expertise in electrospinning. Their in house specialists work closely with clients to assess feasibility, develop proof-of-concept samples, and refine formulations using advanced commercial electrospinning equipment.

One of Nanoscience’s standout strengths is its turnkey support for tech transfer. Once a process is validated through contract development, Nanoscience facilitates the move to internal production by offering equipment sales supported by application specific training and process documentation. This reduces the risk of operational setbacks and accelerates the timeline for bringing electrospun products to market.

Nanoscience operates with a flexible engagement model that supports both instrument sales and contract research services. When acting as a CRO, their approach to intellectual property is designed to balance innovation support with practical commercialization pathways.

For teams with limited bandwidth or evolving needs, Nanoscience also serves as a secondary resource for R&D and manufacturing. Whether it’s overflow production, specialized sample analysis, or iterative development, their contract services can act as an extension of your internal capabilities. This flexibility is especially valuable for organizations that want to scale gradually or maintain optionality in their development strategy.

In short, Nanoscience offers more than just equipment they deliver a partnership model that supports innovation from concept to commercialization, with built-in pathways for growth, support, and strategic control.