Contract Analysis & Method Development

Contract Sample Analysis

We routinely run quality control checks, QC/QA methods, support material development, and failure analysis.

We utilize several techniques for contract analysis services

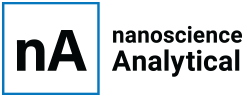

We provide SEM imaging, elemental analysis, statistical particle analysis, fiber and pore analysis, and sample preparation services.

Contact angle, surface tension, surface free energy, powder wettability, and interfacial tension are common methods we employ.

Quartz-crystal microbalance is used to measure nanoscale mass interactions between liquid and solid surfaces, such as nanoparticles, proteins, surfactants, and hydrolysis.

DLS is an optical technique used to determine the size distribution of small particles in suspension including metallic or polymeric nanoparticles and surfactant or lipid micelles.

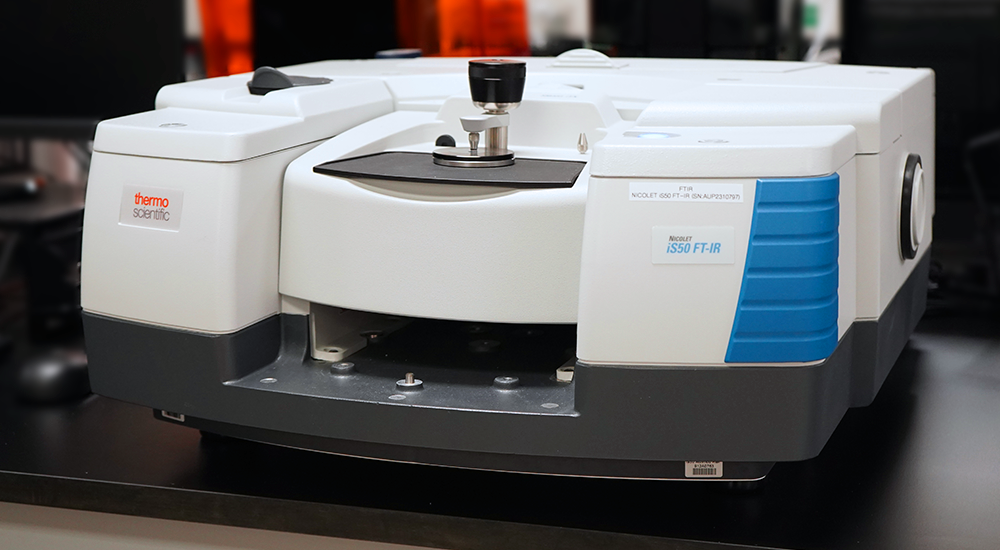

We offer state-of-the-art FTIR spectroscopy services to provide fast, accurate chemical analysis of a wide range of materials. This powerful technique detects and identifies molecular bonds by analyzing how a sample absorbs infrared (IR) light.

Sample Evaluation

We begin every sample analysis project with a detailed discussion with you to evaluate the materials to be analyzed and the types of analysis available. Once the analyses to be performed have been determined, the type of data reporting and format is discussed to suit the customer’s needs. We can develop analysis methods that are designed to meet ASTM or ISO standards.

We guarantee that an identical analysis design will be followed for existing customers who would like to repeat a previous experiment.

Sample preparation is key to many analyses. We utilize several sample preparation techniques and run feasibility tests to evaluate the different techniques. We aim to optimize sample preparation to deliver quality results.

Method Development

If a method exists for the sample and analysis required, then it is used for analysis and reporting.

If an existing method needs to be customized or a new one developed, then the following steps are followed:

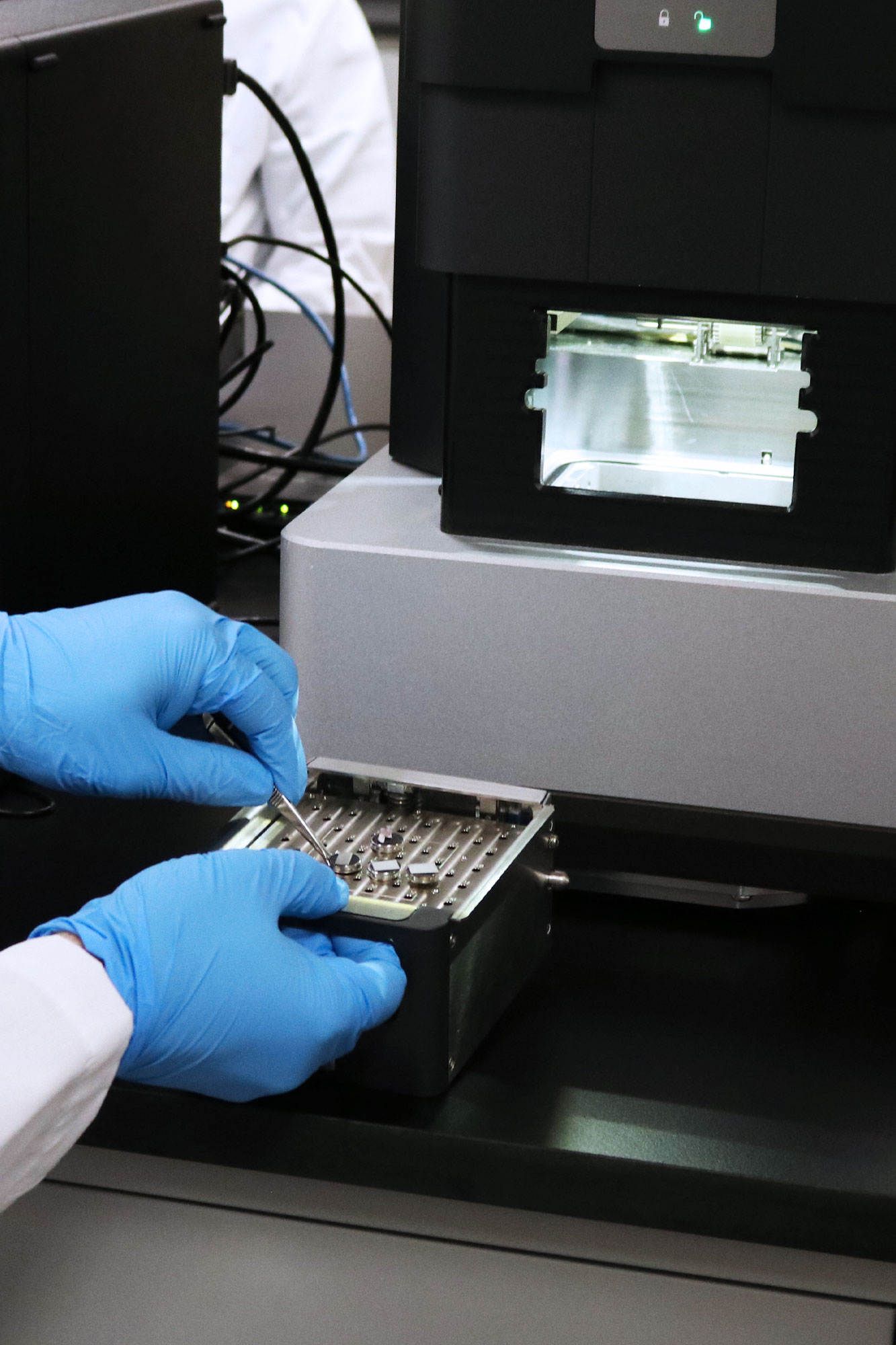

- Different sample preparation methods are evaluated and an optimal one is chosen.

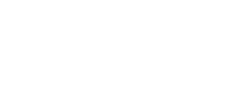

- The instrument is set up and initial checks are performed to test the calibration.

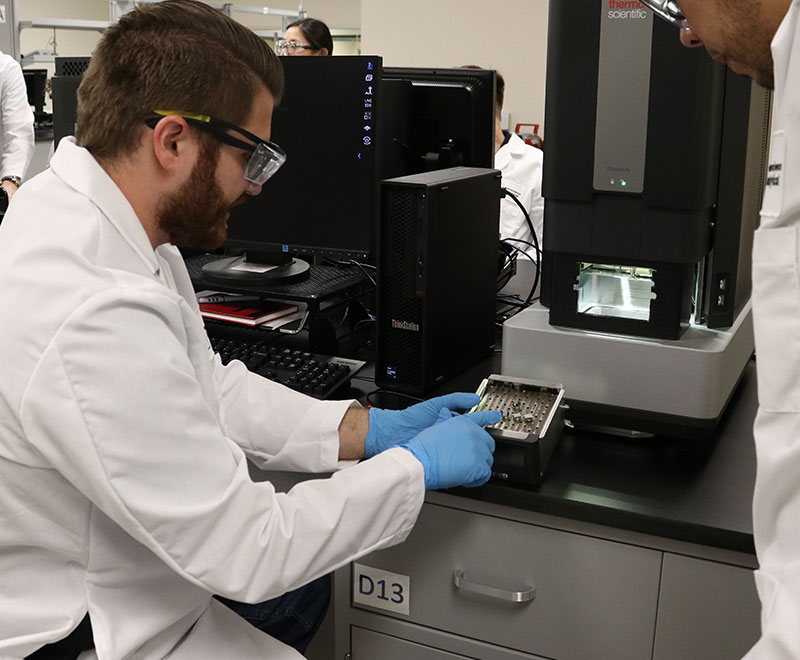

- The sample is mounted or inserted into the instrument.

- Data collection process is optimized.

- The process is automated, if applicable.

- The entire process is documented and repeated.

- The process is inspected for quality assurance.

Talk to a scientist today!

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.

Analysis and Reporting

Our goal is to provide consistent analysis for our customers. Much of our analysis is routine, and a standard operating method is used by all scientists to maintain consistency. In case a modified method or a newly developed method is used, quality assurance programs are in place to ensure consistency. Once the data collection is complete, a scientist will review all the data. The data will be collected into the report identified during the initial consultation and delivered to the customer.

Method Documentation

All processes developed are repeated and documented to allow for future work where any scientist can reproduce the data reliably.

Contact Us

We are a multi-disciplinary laboratory committed to providing our expertise and efficient analytical services.