Electrospinning is a powerful technique for producing nanofibers, yet it’s often described as more art than science. Researchers frequently refer to it as “black magic” because of its sensitivity to a vast array of variables, many of which interact in unpredictable ways. A slight change in polymer concentration, solvent choice, or ambient humidity can dramatically alter fiber morphology, stability, or even the ability to spin at all.

Ultimately, electrospinning is a process of targeted material design. Whether the goal is to create nanofibers for drug delivery, scaffolds for regenerative medicine, or filtration membranes, the ability to control fiber characteristics is essential. Achieving these targeted outcomes requires a holistic understanding of the electrospinning process, where every variable from the chemistry of the solution to the mechanics of the system and the conditions of the environment plays a defining role.

The Complexity of Electrospinning: More Than Meets the Eye

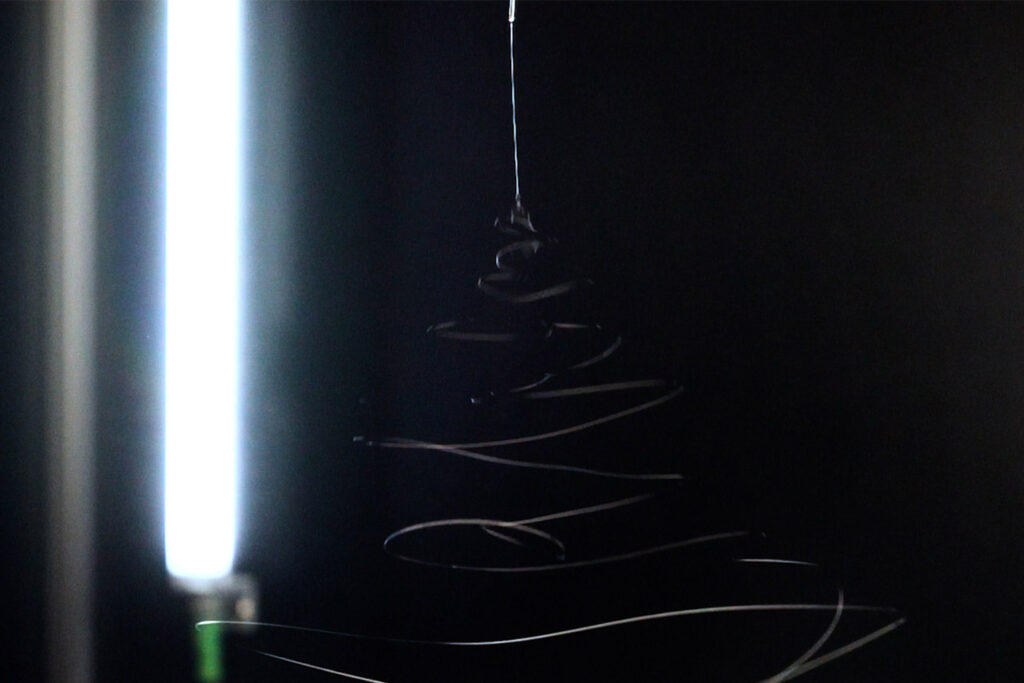

Electrospinning process development is governed by the careful interplay between formulation and electrospinning system parameters, shown in Figure 1. Voltage, flow rate, needle gauge, working distance, and collector motion are not just technical settings, they are levers that shape fiber morphology, influence jet stability, and determine deposition patterns. A mismatch between formulation and system parameters can lead to dripping, clogging, or erratic fiber formation, undermining the entire process.

Equally important are the environmental conditions in which electrospinning occurs. Humidity and temperature, often treated as background variables, can have profound effects. High humidity may cause fibers to fuse or bead due to delayed solvent evaporation, while low humidity can lead to brittle fibers and unstable jets. Temperature shifts influence viscosity and evaporation rates, altering the dynamics of the Taylor cone and the consistency of fiber production. Without active control or compensation, these factors introduce variability that can derail even the most carefully designed experiments.

Experimental Design for Optimized Electrospinning

Given the complexity of electrospinning and the multitude of variables involved, the common approach, changing one variable at a time while holding others constant may seem logical, but it’s fundamentally flawed in a system where interactions between variables are not only common but often decisive. In electrospinning, where the behavior of the system is shaped by the interplay between formulation chemistry, equipment settings, and environmental conditions, a multivariate approach is not just helpful, it’s essential.

Factorial DOE is not a niche tool, it’s a standard practice in sectors where the cost of inefficiency is high and the demand for performance is uncompromising. In pharmaceutical development, for example, DOE is used to optimize drug formulations, identify critical process parameters, and satisfy regulatory requirements for quality by design (QbD). Instead of testing one variable at a time, DOE allows researchers to evaluate multiple factors simultaneously, uncovering not just individual effects but critical interactions. This multivariate approach transforms electrospinning from a trial and error process into a predictable, tunable system. Whether the goal is to scale up production, improve reproducibility, or tailor nanofiber properties for a specific application, DOE provides the framework to do so efficiently and scientifically.

A full factorial matrix with three factors at two levels requires eight experiments, compared to just six in a single-variable-at-a-time (SVAT) approach. But this modest increase in effort yields exponentially greater insight. While SVAT can only reveal the isolated effect of each variable, factorial DOE uncovers how variables interact a critical capability in electrospinning, where the behavior of one parameter often depends on the setting of another. Moreover, factorial DOE supports predictive modeling. Once the relationships between variables and outcomes are mapped, researchers can simulate new conditions without running additional experiments.

Basic Factorial DoE Matrix (22)

| Experiment Number | Variable 1 | Variable 2 |

| 1 | + | + |

| 2 | + | – |

| 3 | – | + |

| 4 | – | – |

Designing for Precision: Case Study “The Power of Factorial DOE in Electrospinning”

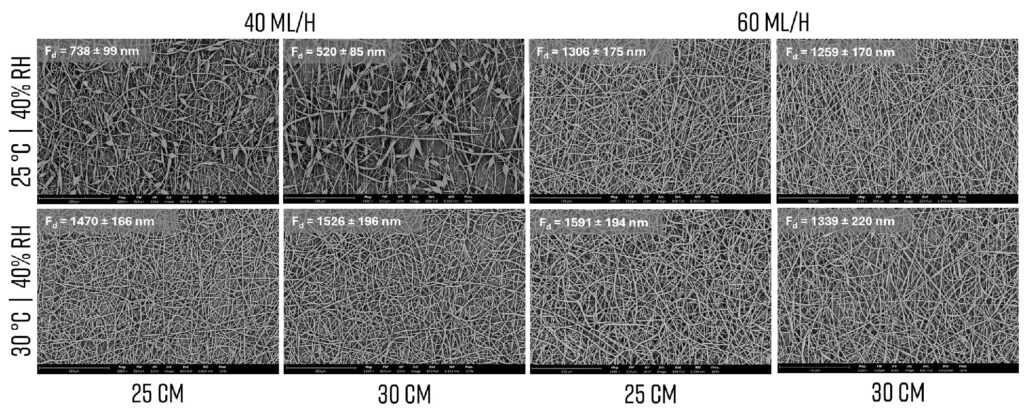

In a recent study, a fixed polymer formulation was electrospun using a 20-needle setup to evaluate the effects of flow rate, working distance, and environmental conditions (temperature and relative humidity), at two levels each.

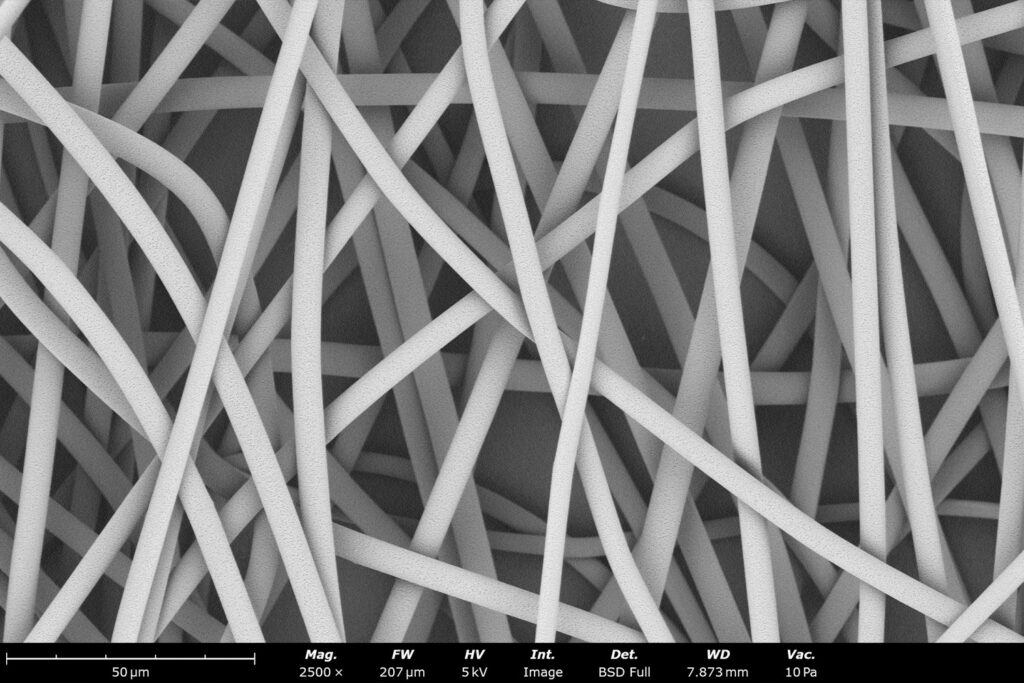

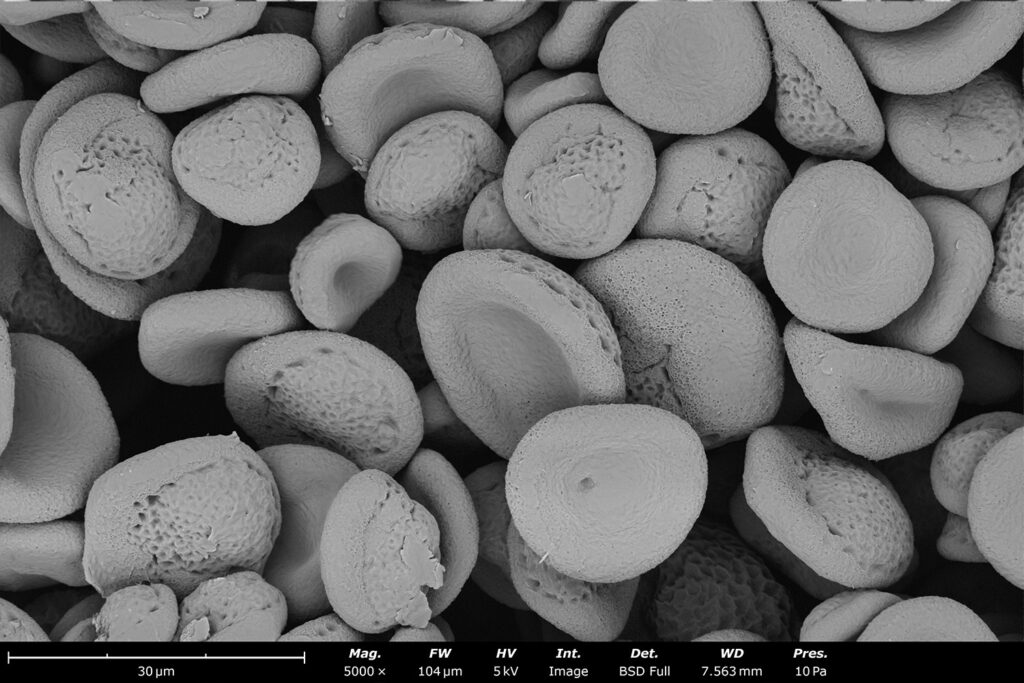

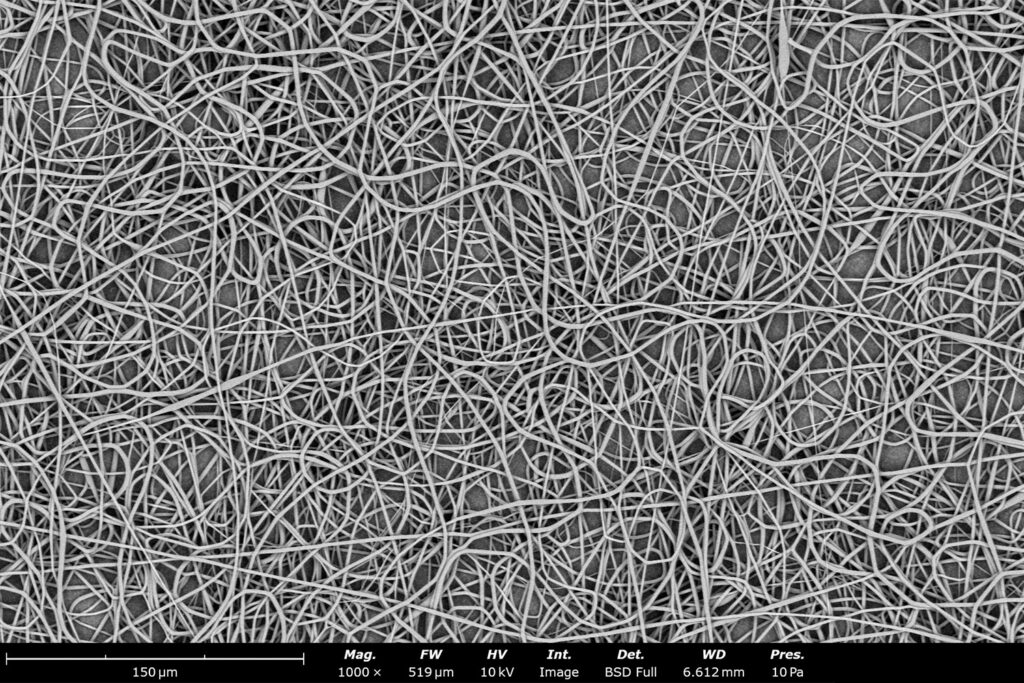

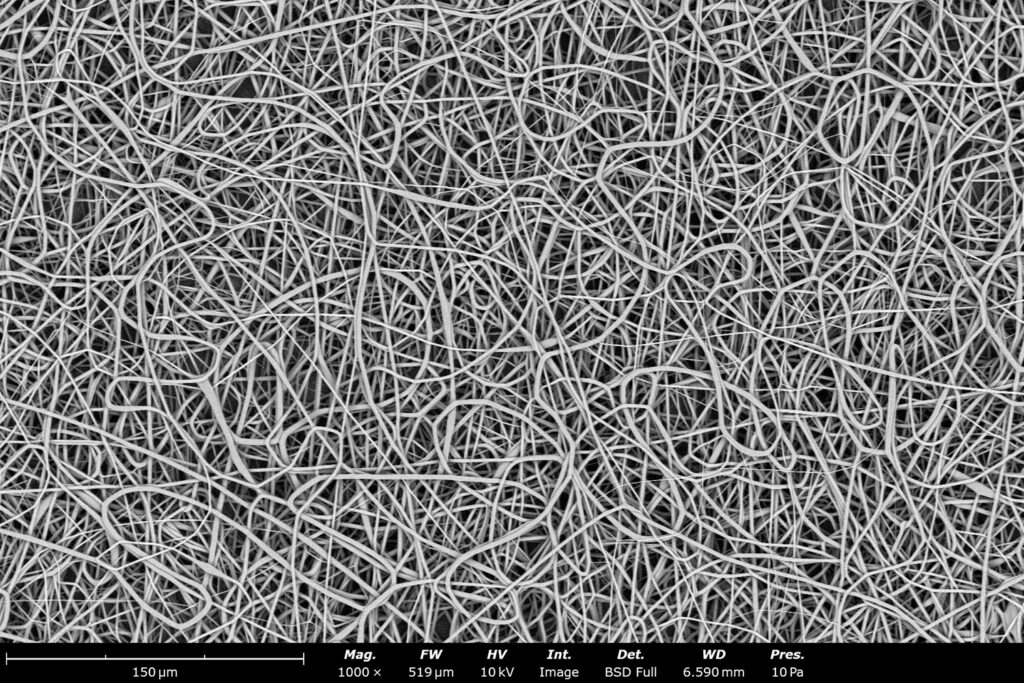

At 25 °C, increasing the flow rate from 40 mL/h to 60 mL/h transformed fiber morphology from beaded structures to uniform fibers, indicating that higher throughput can stabilize jet formation under controlled conditions. Similarly, raising the temperature from 25 °C to 30 °C while maintaining a constant flow rate of 40 mL/h produced the same improvement from beaded fibers to evenly formed fibers, highlighting the critical role of thermal conditions in solvent evaporation and jet stability.

The strength of a multivariate approach becomes evident when examining interactions between parameters. Two additional experiments conducted at 30 °C with (40 mL/h, 30 cm) and (60 mL/h, 25 cm) would not have been included in a single-variable-at-a-time study. These runs produced the largest recorded fiber diameters of the entire set: 1526 ± 196 nm and 1591 ± 194 nm, respectively. Such findings underscore the importance of exploring parameter combinations rather than isolated factors.

By leveraging factorial experimental design, we were able to identify synergistic effects between flow rate, temperature, and working distance, enabling optimization for maximum fiber diameter at the fastest production rate. This approach not only accelerates development but also ensures reproducibility and scalability, critical for transitioning electrospinning from research to commercial manufacturing.

From Complexity to Control: Electrospinning Reimagined

When approached with the right tools and mindset, electrospinning becomes a controllable, tunable process capable of delivering precise, application-specific outcomes. By evaluating multiple variables and their interactions simultaneously, DOE enables teams to design toward specific outcomes, whether that’s fiber diameter, orientation, drug release profiles, or process stability. It’s a scientific approach that replaces guesswork with precision, and it’s the key to unlocking electrospinning’s full potential.

As a contract research organization (CRO) with extensive experience in electrospinning and nanomaterials characterization, Nanoscience Analytical offers a unique advantage. Our team understands the nuances of polymer-solvent interactions, the subtleties of jet stability, and the critical role of environmental control.

Whether you’re developing a new electrospun product, troubleshooting an unstable formulation, or preparing for scale-up, partnering with Nanoscience Analytical can accelerate your progress. We bring the tools, the expertise, and the scientific rigor needed to turn electrospinning into a predictable, repeatable, and commercially viable process.